咨询热线0730-1234567

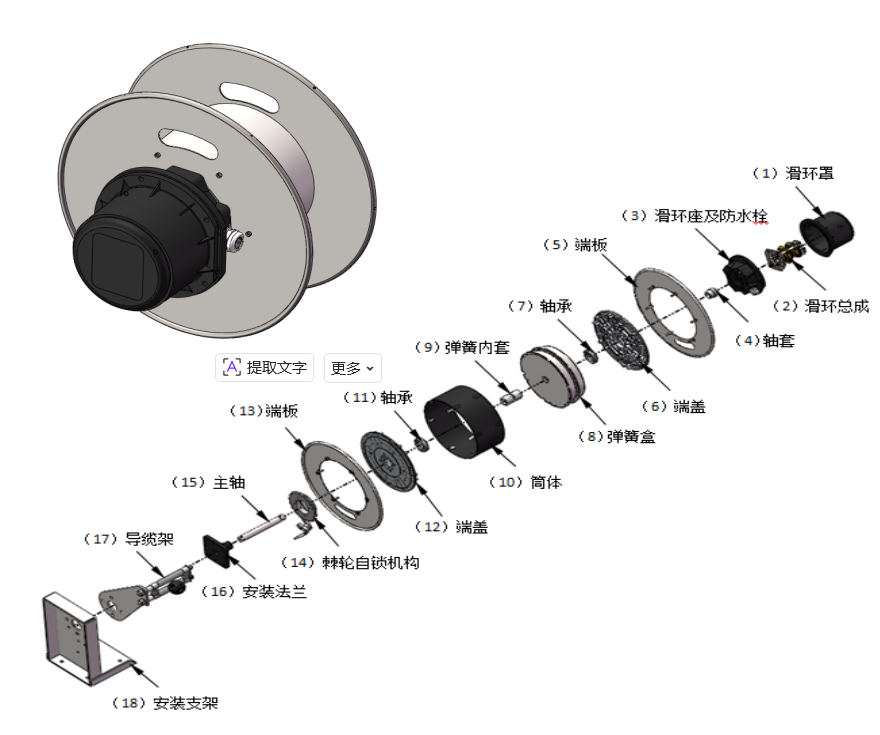

湖南省岳阳市岳阳国际企业港二期第2#号楼101弹力驱动式电缆卷筒是采用涡卷弹簧作为驱动源自动收取电缆的机械装置,主要由电缆卷筒、弹簧马达、滑环组件、安装法兰或支座、及各种可选附件组成。其基本结构如下面图示。

S19H系列弹力驱动式电缆卷筒结构图:

卷筒筒体:

卷筒体由冷轧钢板卷制,两侧端板采用镀锌板,外沿作卷边处理,卷筒体及端板表面作喷塑防护处理。端板用螺栓固定在筒体上,弹簧马达装在卷筒体内,筒体两端安装有长寿命的润滑球轴承。

弹簧马达:

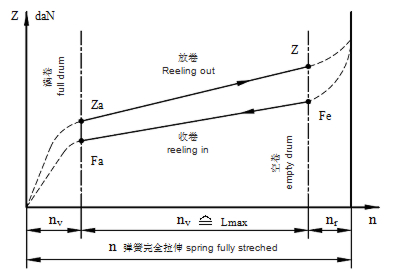

弹簧采用特殊弹簧钢特制,特殊要求下,其使用寿命可达10万次,卷筒使用寿命长,适合恶劣及高频度使用环境,工作时扭矩线性好,确保电缆在收放过程中所受弹簧张力柔韧平滑,延长电缆的使用寿命。弹簧工作特性如下面图示:

Lmax=最大卷取电缆长度

na=弹簧工作时允许的最大转动圈数

nv=弹簧预紧张力必须的转动圈数

nr=弹簧保留的转动圈数

Fa=完全缠绕电缆时的拉力

Fe=电缆完全放出时回收的张力

Z=放出电缆时所需的拉力

HINAR公司根据不同规格电缆的卷绕要求,设计和提供多种规格的驱动弹簧。这些弹簧可通过并联而获得较大的工作扭矩,或通过串联而获得较多的工作圈数,或并联与串联同时使用,即可获得较大的工作扭矩,又可获得较长的卷绕能力,以满足用户不同工况的使用要求。

滑环组件:

主要用来传输电能或数据信号。绝缘等级一般为F级,特殊要求可达H级

1、动力:电压690V,交流400A。相数可根据用户要求叠加。

2、控制:500V-AC或直流≤24A。可达60相

3、数据传输:采用水银滑环或贵金属刷导技术,确保控制、测量图像或计算机信号不失真。

4、光信号:采用光纤旋转接头,最多12相,工作圈数60圈以内。

滑环罩采用塑胶部件或冲压成型(基本取消焊接工艺),模块化装配技术集约而成,部件结合处均整体密封性好,防护等级高,一般为IP55,特殊要求可达IP56。

安装法兰:

依据不同工况的使用要求,HINAR弹力驱动式电缆卷筒配有容易安装的安装法兰或L型支座。安装法兰或支座表面都经过喷塑防护处理。

选配附件及功能:

附件如棘爪自锁机构、电缆钢丝保护网、封闭式滚轮、导向装置等。

辅助功能如电辅加热、限位开关等。

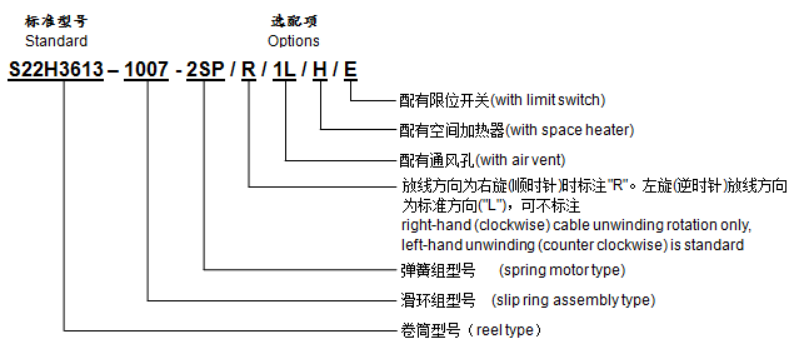

型号说明:

卷取方式(Typical Applications)

|

|

A方式:卷筒固定垂直收放电缆 Vertical application: The cable is unreeled vertically downwards (downward inclination). Alternatively the cable is unreeled vertically upwards (upward inclination). | D方式:卷筒移动,双向自由收放电缆,电缆置于地面上 Horizontal mobile application: The cable is unreeled on a flat and continuous surface. The cable is unreeled horizontally in either travelling directions. |

|

|

2D方式:卷筒移动,水平方向通过导线轮收放电缆,电缆置于托棍上 Horizontal mobile application: The cable is reeled out on supports (L1 < 1m) or on rollers or rounded smooth supports (L1 = 1 to 3 m, depending on the cable size). The cable is unreeled horizontally in either travelling directions. | 1F方式:卷筒移动,悬空双向收放电缆电缆不拖地 Horizontal mobile application: The cable is unreeled horizontally, above the ground and without support, in either travelling directions.

|

|

|

C方式:卷筒固定,悬空安装,设备移动,卷筒双向收放电缆,电缆置于托棍上 Stationary application: The cable is unreeled horizontally in either travelling directions through support rollers (L1 = 1 to 3 m, depending on the cable size). | 1D方式:卷筒移动,双向导向收放电缆,电缆置于地面上 Horizontal mobile application: The cable is unreeled on a flat and continuous surface. The cable is unreeled horizontally in either travelling directions. |

|

|

3D方式:卷筒移动,水平双向自由收放电缆,电缆置于托棍上 Horizontal mobile application: The cable is reeled out on supports (L1 < 1m) or on rollers or rounded smooth supports (L1 = 1 to 3 m, depending on the cable size). The cable is unreeled horizontally in either travelling direction. | 2F方式:卷筒固定,设备移动,卷筒悬空双向收放电缆,电缆不拖地 Horizontal mobile application: The cable is unreeled horizontally, above the ground and without support, in either travelling directions. |

Lw= 最大卷取电缆行程 maximum reeling cable length h= (安装高度)电缆放置平面至卷筒中心的距离 (installation height) distance between cable deposit plane and drum centre LF= 电缆反馈点 cable feeding point f=最大电缆弧垂 maximum cable sag f1=最大电缆弧垂 maximum cable sag L1=托棍支撑间距 roller or support distance H8/9= 最大的电缆悬垂长度 maximum cable length hanging down from the drum | |

S19H型选型表

S19H type Selection Tables for Reels

电缆 Cable | 卷取方式 | 电缆长度 Lw/Li (m) | 卷筒型号 Reel type | D (mm) | a (mm) | b (mm) | 滑环箱 Slipring-body | 法兰 Flange type |

4×1.5mm2 Φ9.2mm 0.133kg/m

| A | 6/1.5 | S19H2914-0304-1A | 290 | 175 | 136 | 1 | 1.1 |

D | 6/1.5 | |||||||

A | 12/1.5 | S19H3314-0304-2S | 330 | 175 | 136 | 1 | 1.1 | |

D | 12/1.5 | |||||||

A | 20/1.5 | S19H3614-0304-3S | 360 | 175 | 136 | 1 | 1.1 | |

D | 20/1.5 | |||||||

5×1.5mm2 Φ10.1mm 0.143kg/m

| A | 6/1.5 | S19H2914-0305-1A | 290 | 175 | 136 | 1 | 1.1 |

D | 6/1.5 | |||||||

A | 12/1.5 | S19H3314-0305-2S | 330 | 175 | 136 | 1 | 1.1 | |

D | 12/1.5 | |||||||

A | 20/1.5 | S19H3614-0305-3S | 360 | 175 | 136 | 1 | 1.1 | |

D | 20/1.5 | |||||||

7×1.5mm2 Φ11 mm 0.19kg/m

| A | 6/1.5 | S19H2914-0307-1A | 290 | 220 | 136 | 1 | 1.1 |

D | 6/1.5 | |||||||

A | 12/1.5 | S19H3314-0307-2S | 330 | 220 | 136 | 1 | 1.1 | |

D | 12/1.5 | |||||||

A | 20/1.5 | S19H3614-0307-3S | 360 | 220 | 136 | 1 | 1.1 | |

D | 20/1.5 | |||||||

8×1.5mm2 Φ14.5mm 0.312kg/m | A | 6/1.5 | S19H3314-0208-1A | 330 | 220 | 136 | 1 | 1.1 |

D | 6/1.5 | |||||||

A | 12/1.5 | S19H3614-0208-2S | 360 | 220 | 136 | 1 | 1.1 | |

D | 12/1.5 | |||||||

A | 20/1.5 | S19H3614-0208-3S | 360 | 220 | 136 | 1 | 1.1 | |

D | 20/1.5 |

电缆 Cable | 卷取方式 | 电缆长度 Lw/Li (m) | 卷筒型号 Reel type | D (mm) | a (mm) | b (mm) | 滑环箱 Slipring-body | 法兰 Flange type |

4×2.5mm2 Φ10mm 0.179kg/m | A | 6/1.5 | S19H2914-0204-1A | 290 | 175 | 136 | 1 | 1.1 |

D | 6/1.5 | |||||||

A | 12/1.5 | S19H3314-0204-2S | 330 | 175 | 136 | 1 | 1.1 | |

D | 12/1.5 | |||||||

A | 20/1.5 | S19H3614-0202-3S | 360 | 175 | 136 | 1 | 1.1 | |

D | 20/1.5 | |||||||

5×2.5mm2 Φ12mm 0.22kg/m | A | 6/1.5 | S19H3314-0205-1A | 330 | 175 | 136 | 1 | 1.1 |

D | 6/1.5 | |||||||

A | 12/1.5 | S19H3314-0205-2S | 330 | 175 | 136 | 1 | 1.1 | |

D | 12/1.5 | |||||||

A | 20/1.5 | S19H3614-0205-3S | 360 | 175 | 136 | 1 | 1.1 | |

D | 20/1.5 | |||||||

7×2.5mm2 Φ14.8mm 0.334kg/m | A | 6/1.5 | S19H3314-0207-1A | 330 | 220 | 136 | 1 | 1.1 |

D | 6/1.5 | |||||||

A | 12/1.5 | S19H3614-0207-2S | 360 | 220 | 136 | 1 | 1.1 | |

D | 12/1.5 | |||||||

A | 20/1.5 | S19H3614-0207-3S | 360 | 220 | 136 | 1 | 1.1 | |

D | 20/1.5 | |||||||

4×4mm2 Φ14mm 0.322kg/m | A | 6/1.5 | S19H3314-0204-1A | 330 | 175 | 136 | 1 | 1.1 |

D | 6/1.5 | |||||||

A | 12/1.5 | S19H3614-0204-2S | 360 | 175 | 136 | 1 | 1.1 | |

D | 12/1.5 | |||||||

A | 20/1.5 | S19H3614-0204-3S | 360 | 175 | 136 | 1 | 1.1 | |

D | 20/1.5 |

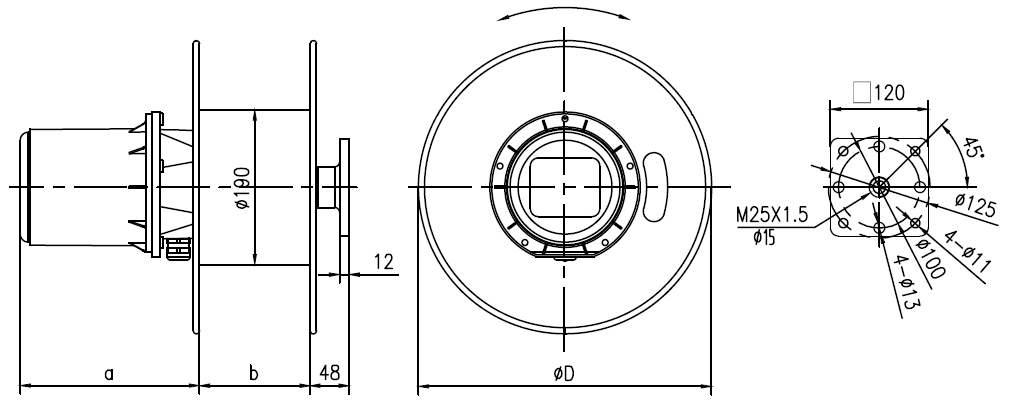

技术参数:Technical parameters:

材料及构造:卷筒本体及安装法兰采用钢件制造。弹簧为高寿命高等级的弹簧钢。

Materials &Structurction: The drum body and mounting flange are made of steel. Spring is the high life high-grade spring steel.

卷绕速度:水平卷绕 63m/min 垂直卷绕 30m/min

Winding speed: Horizontal : 63m/min Vertical winding: 30m/min

卷取长度:水平最大卷绕长度:20米,垂直最大卷绕长度 20米

Winding length: The Max Horizontal winding length: 20m, The Max Vertical winding length: 20m

电缆参数:外径Max Φ15mm,重量Max 0.46kg/m;

Cable Spec: MaxOD: Φ15mm, Max weight: Max 0.46kg/m;

电气参数:Vmax 500V,Imax 30A

Electric parameter: Vmax 500V,Imax 30A

防护等级:IP54

Grade: IP54